Night Guardian: the core role of reflective cloth

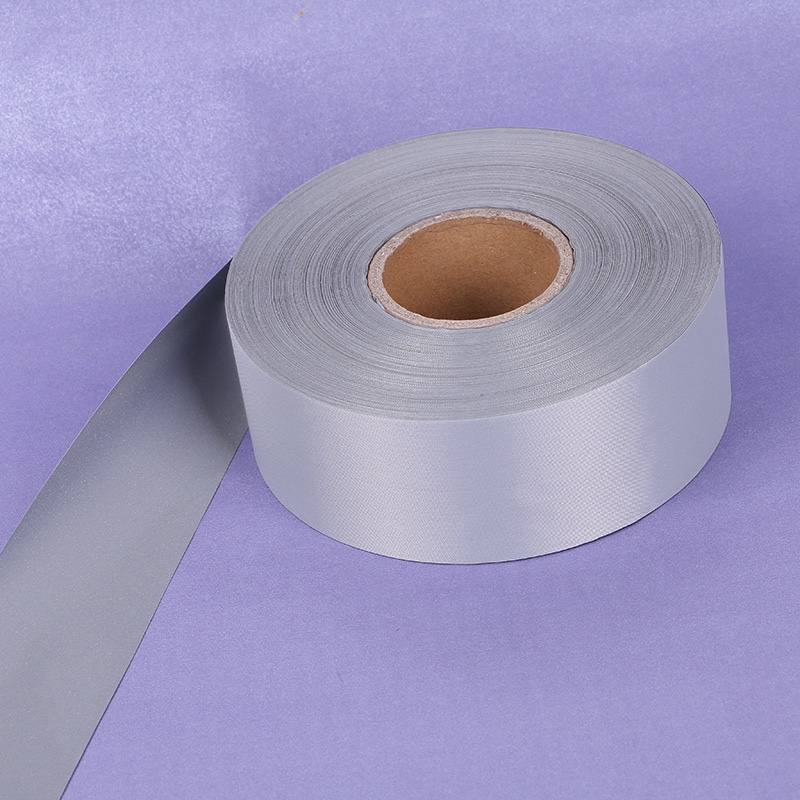

When walking or riding in the dark, visibility is often the key factor in determining safety. The high-performance reflective cloth significantly reduces the risk of accidents by greatly improving personal visibility in low light conditions through advanced optical reflection technology. These materials typically employ two primary reflective mechanisms: microbead technology and glass microsphere coatings.

Microbead technology uses small transparent plastic particles to capture light and reflect it back in the same direction to form a strong retroreflective effect; while glass microspheres are a layer of small hollow glass beads attached to the surface of the fabric, which will produce bright spots when the car lights are illuminated. Although both can improve visibility, microbeads are more durable and less prone to fading, while glass microspheres are less expensive but easily damaged. According to the National Highway Traffic Safety Administration, wearing high-visibility clothing can reduce the incidence of traffic accidents by about 70%.

Omni-directional protection: multi-scenario application example

The application of reflective cloth goes far beyond clothing and accessories. Now it has penetrated into every aspect of our lives-running clothes, mountain backpacks, construction site helmets and even signs on public transport vehicles. Every detail tells the great contribution of this small invention to mankind in silence.

For example, a morning runner once shared a story about an early morning workout when he suddenly encountered heavy fog and his sight was severely blocked. Fortunately, she wore a sports vest with obvious reflective strips and successfully avoided the dangerous road with the help of passing drivers. Similar deeds are numerous, and each case demonstrates the irreplaceable value of reflective cloth.

Good Material Selection: High Quality Materials Achieve Reliability

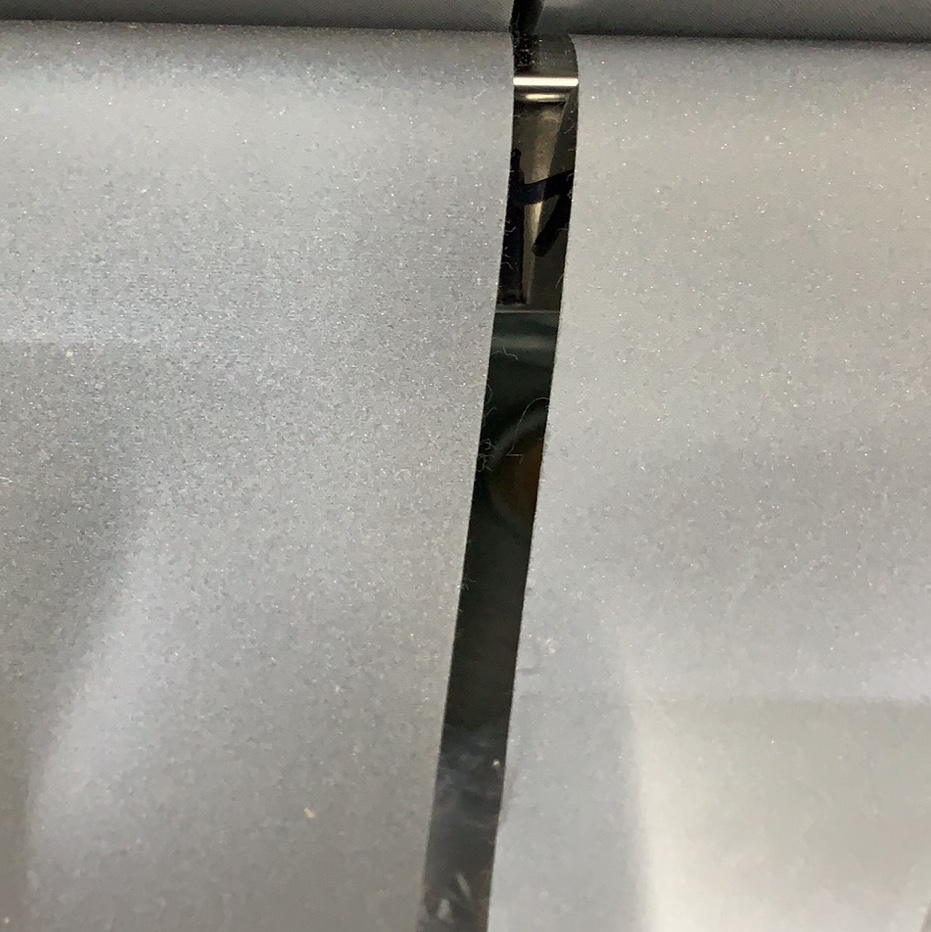

An excellent reflective cloth can not be separated from the support of high-quality raw materials and technical processes. Polyester fiber has become one of the preferred substrate materials due to its excellent wear resistance and flexibility. In the reflective layer, a variety of metal oxide films such as aluminum silver alloy and titanium dioxide are widely used. These substances give the finished product a very high brightness value and a smooth feel.

It is particularly worth mentioning that certain combinations can make the finished product light and durable while also having excellent luminous efficiency. For example, a new type of composite fabric made by combining high-strength polyester yarn with nanoscale ceramic powder has well balanced the contradictory relationship between strength and weight, and achieved an unprecedented breakthrough.

Details Determine Success or Failure: Design and Ergonomic Considerations

A good product must not only pay attention to the appearance, but the inner ergonomic design is equally important. Modern reflective fabric designers know this well, they carefully plan the proportion of each part of the size and fixed way, and strive to achieve the best wearing experience. Reasonable location layout not only helps to enhance the visual impact, but also ensures that the comfort of long-term use is not affected.

In order to meet the needs of different groups of people, there are many unique design concepts on the market, such as adjustable straps that allow users to adjust the degree of tightness, and flexible embedded reflective strips that can be changed at will according to actual needs. These ingenious ideas undoubtedly greatly increase the practicality, so that people enjoy a more personalized service.

Green: The Choice of Sustainable Development

With the increasing awareness of global environmental protection, more and more enterprises begin to pay attention to their own sense of social responsibility. The reflective fabric industry is no exception. Many well-known brands have joined the tide of energy saving and emission reduction, and strive to find more environmentally friendly and efficient production methods. Start from the source, select non-polluting raw materials and optimize the processing process to minimize energy consumption and waste emissions.

At the same time, some companies have launched recycling programs to encourage consumers to return their old products in exchange for preferential treatment